Measurement & Analysis Instruments > Safety Instrument

Include ISO 17025 CNAS & ILAC Calibration Certificate

Origin: China Guangdong

Item No.: LX-IK04

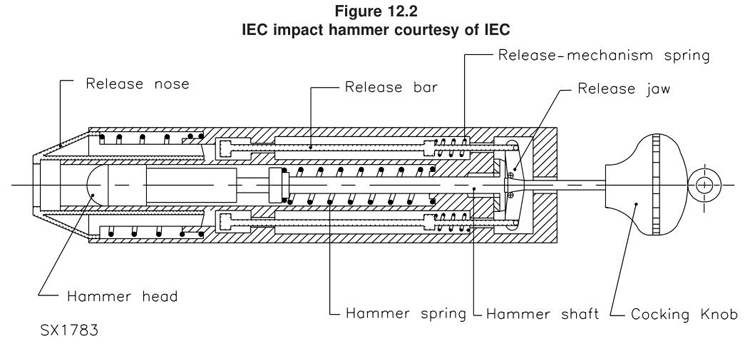

0.5J IEC Impact Hammer Courtesy of UL 1244 Figure 12.2 (SX1783)

Impact Emergy | MPE |

0.5 J | ± 0.04J |

Note:

The apparatus consists of three main parts: the body, the striking element, and the spring-loaded release nose.

Note 1:

The body comprises the housing, the striking element guide, the release mechanism, and all parts rigidly fixed thereto. The mass of this assembly is 1.25 kg (2.756 lb mass).

Note 2:

The striking element comprises the hammer head, the hammer shaft, and the coking knob. The mass of this assembly is 250 g (8.81 oz. mass).

Note 3:

The hammer head has a hemispherical face of radius 10 mm (25/64 inch), and is of polyamide having a Rockwell hardness of R100; it is fixed to the hammer shaft in such a way that the distance from its tip to the plane of the front of the nose, when the striking element is on the point of release, is 20 mm (25/32 inch).

Note 4:

The nose has a mass of 60 g (2.1 oz. mass) and the nose spring is such that it exerts a force of 20 N (4.5 lbf) when the release jaws are on the point of releasing the striking element.

Note 5:

The hammer spring is adjusted so that the product of the compression, in millimeters, and the force exerted in newtons, equals 1000 (in pound-inches, 8.85), the compression being approximately 20 mm (25/32 inch). With this adjustment, the impact energy is 0.5 0.05 N m (4.43 0.443 pound force-inch).

Note 6:

The release mechanism springs are adjusted so that they exert just sufficient pressure to keep the release jaws in the closed position.

Note 7:

The apparatus is cocked by pulling the cocking knob back until the release jaws engage with the groove in the hammer shaft.

Note 8:

The blows are applied by pulling the release nose against the sample in a direction perpendicular to the surface at the point to be tested. The pressure is slowly increased so that the nose moves back until it is in contact with the release bars, which then move to operate the release mechanism and allow the hammer to strike.

Company introduction

HK LEE HING INDUSTRY CO., LIMITED are specialized in manufacturing special, custom built, test and measuring equipment for products testing as per international norms and offering calibration services and related information. Our products and services are used by research & development establishments, test laboratories, defense establishments, government institutions & manufacturing industries to fulfill the clients' requirements.

Main Products: Go No Go Gauges, IP Tester, Test Probe Kit, Impact Test Equipment, Test Probes, Spring Hammer, IEC 61032 Test Finger, AC Hipot Tester, IEC Test Probe, UL Test Probe, Material Flammability Tester, IP Code Tester, Impact Test Apparatus, Plugs and Socket Outlet Gauge, Security Testing Machine, Lamp Cap Gauge Tester, Lampholders Gauge Tester, Plug & Socket Tester, Electrical Safety Tester, LED Test Instruments, Environmental Test Equipment, Instrument Accessories, Weighing Sensor and More.

If you require equipment to test products such as home appliances, electrical accessories like switches, sockets, connectors, etc. industrial & road lighting luminaires, automobile lighting systems or related categories, we can provide the solutions you need.

We would appreciate your comments on the layout design, presentation or other aspects of our website.

Website: https://www.china-gauges.com

Contact information

Contacts: Nina She

E-mail: sales@china-gauges.com

TEL: +86-755-33168386

FAX: +86-755-61605199

Phone: +86-15919975191

SKYPE: nina.she@outlook.com

Address: 1F Junfeng Building, Gongle, Xixiang, Baoan District, Shenzhen, Guangdong, China

ZIP: 518102

Website: http://www.china-gauges.com/

Contact: Eason Wang

Phone: +86-13751010017

E-mail: sales@china-gauges.com

Add: 1F Junfeng Building, Gongle, Xixiang, Baoan District, Shenzhen, Guangdong, China